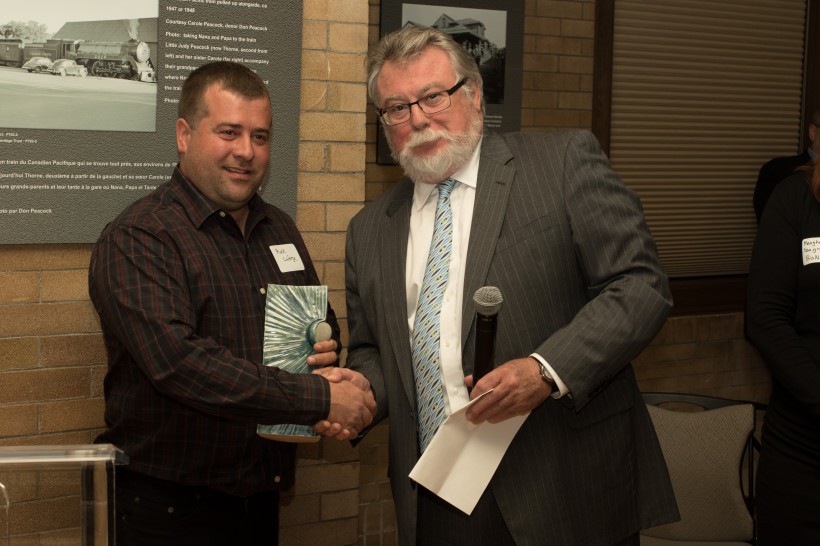

You could say Rock Laforge operates the dairy farm of the future, and that’s why he received the 2015 New Brunswick Bioscience Achievement Award from BioNB.

A fourth-generation farmer from Saint-Andre (50 kilometres southeast of Edmundston), Laforge heads Laforge Bioenvironmental, which powers his farm by burning the gas produced by waste products. The residue is then used as fertilizer. The facility even produces enough electricity that it sells some to NB Power’s grid.

“We can only supply 1,000 kilowatts to the grid now … but eventually we may bring it up to 1,500 kilowatts,” Laforge said in a phone interview Wednesday.

The biogas facility represents a $7-million investment in two plants and together they generate clean, renewable energy.

The system comprises two anaerobic digesters that take waste such as manure and other residues from the Laforge farm and other neighbouring food producers. The waste is mixed and fed into the digesters so that it produces methane as the organic material breaks down. Each digester comprises a lagoon covered by a flexible membrane that captures the methane as it escapes the mixture. The methane — a form of natural gas — is then burned to power an electrical generator.

Related: In Praise of NB's Biotech Community

Laforge said he set up his first digester, with a 1,500-cubic-metre capacity, about seven years ago, and it was so successful that it led to the recent construction of a second digester with a capacity of 10,000 cubic metres.

The two plants generate enough energy to power the entire dairy operation and 1,000 homes in the area.

Once the mixture is completely broken down, the residue is a rich organic compost that Laforge uses as fertilizer.

“The Laforge facility is a compelling example of true New Brunswick resourcefulness, transforming residuals from local agriculture and food processors into sustainable, high-value products,” BioNB said in the news release that announced the award. “The Laforge family has a true entrepreneurial spirit, and they use the expertise learned from their own operations to help other farmers build similar projects.”

Laforge said he has worked closely on the project with the New Brunswick Community College Biorefinery Technology Scale-up Centre, whose researchers have helped in determining the optimum blend to produce the most methane possible.

He said he receives a payback for the capital investment over a 10-year period, so within three years from now the initial tank will have paid for itself. In addition to reducing his heating and electricity costs, he does not have to buy fertilizer, which further reduces his operating expenditures.

Laforge envisages expanding the operation in the future as other farms become more familiar with the operation. His farm is a 400-hectare operation, but the total farmland that could be using such an operation in his vicinity amounts to 3,200 hectares.

BioNB said the other finalists for its annual award were: Mycodev Group of Fredericton, which developed a new method of producing chitosan, a material that has numerous commercial applications in such fields as medicine, agriculture, wine or industry; and Erik Scheme, the NB Innovation Research Chair in Medical Devices, who is active in the medical technologies industry in Atlantic Canada.