Metamaterial Technologies Inc. of Halifax has signed a $5.6 million agreement with aerospace giant Lockheed Martin to develop materials that enhance solar power and can be used on aircraft.

MTI issued a statement on Thursday saying that the partners will work on the development of metaSOLAR, which incorporates advanced, lightweight materials, suitable for flights.

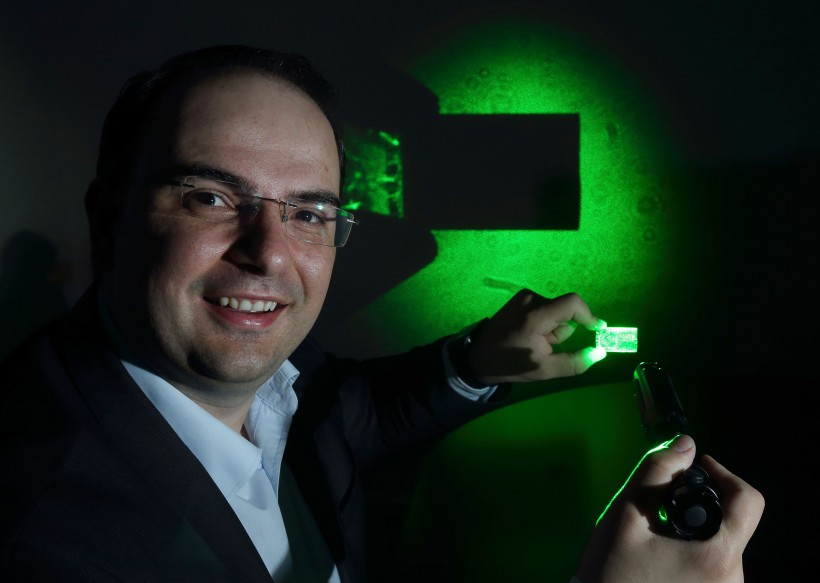

MTI is dedicated to producing metamaterials – materials whose compounds are not found in nature – that have an impact on light. The company, which announced an $8.3 million funding round earlier this year, is already working with Airbus to produce metaAIR, a transparent screen that filters out laser beams. Now the company is moving into its second product line, solar power, and again working with one of the world’s leading aerospace companies.

“We are honored to be supported by Lockheed Martin,” said MTI Founder and CEO George Palikaras in the statement. “This agreement will allow us to accelerate the development of metaSOLAR as we aim to enter the solar market by providing advance photovoltaic technology to the aerospace and defence industry. MetaSOLAR will be ideal for harvesting energy in the transportation industry beyond aviation.”

MTI uses the latest achievements in optical science, metamaterials, semiconductors and nanofabrication to make commercial quantities of revolutionary materials. Its patented solar technology has been engineered to collect, trap and absorb solar light from all directions at wide angles, significantly improving efficiency, removing the need to track the sun.

MetaSOLAR incorporates NanoWeb, a highly conductive metal mesh printed on to any surface using MTI’s proprietary Rolling Mask Lithography manufacturing tool. RML is used to manufacture functional materials in a variety of shapes and designs, allowing MTI to create a new class of smart materials for a wide range of applications.

It’s understood that metaSOLAR will be a lightweight material that can be shaped to fit on to any surface. For example, it could eventually be used to line an airplane wing and generate electricity while the plane is in flight.

Dal Eyes First I-Corps Node in Canada

The new partnership marks Lockheed Martin’s first solar investment in Canada. The Bethesda, Maryland-based company already has interests in Atlantic Canada and is a key funder and customer for Halifax-based QRA Corp. which helps manufacturers eliminate design flaws early in the development process. Lockheed Martin is working with MTI through the Industrial and Technological Benefit Policy, under which foreign companies must make investments in Canada in order to bid on Canadian government contracts. Lockheed Martin is making these investments as part of its ITB obligations for the in-service support of the C-130J Super Hercules, a transport aircraft.

“We are pleased to see our ITB investment going to a great Canadian global innovator such as Metamaterial Technologies Inc,” said Charles Bouchard, Chief Executive of Lockheed Martin Canada. “Their work in the field of smart materials and in developing a disruptive solar application suitable for flight is an example of what Canadian technology offers the world.”

The Lockheed Martin announcement is the third major piece of news from MTI this year. In April, MTI unveiled its $8.3 million round of funding, led by Toronto-based venture capital fund Radar Capital Inc. The other backers were Innovacorp and angel investors, including members of the First Angel Network.

In February, MTI and European aircraft maker Airbus announced they would proceed with the commercial production of MetaAir, manufacturing it in Halifax. Palikaras has said the company has three main goals – to produce commercial materials that filter light (metaAIR), enhance the absorption of light (metaSOLAR) and reflect light (a product yet to be revealed).

“Metamaterials are in essence the materials of the future”, said Harry Atwater, Howard Hughes Professor and Professor of Applied Physics and Materials Science at the California Institute of Technology. “MTI is pioneering large scale affordable nanofabrication technology that can push the boundaries for crystalline silicon solar efficiency and create very thin form factors for solar cells.”