What started as a class project for the three engineering students at the University of Prince Edward Island is rapidly showing signs of becoming a viable business.

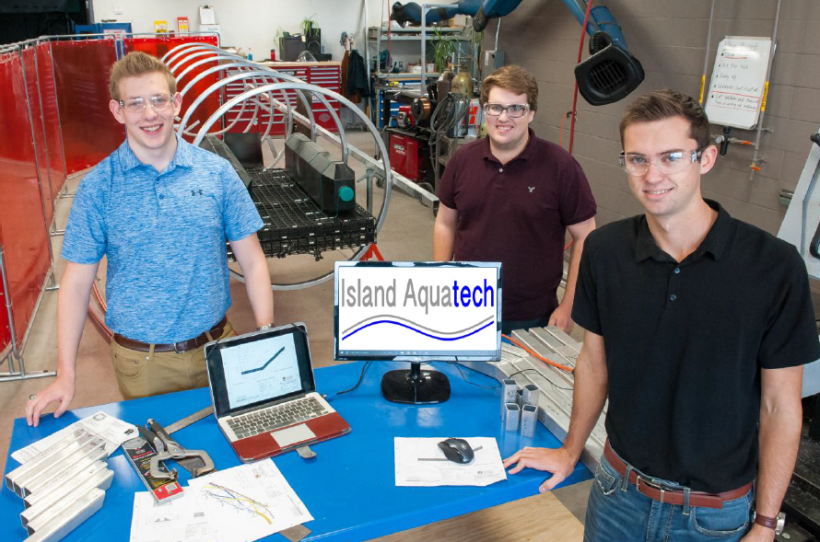

Island AquaTech is the creation of three engineering students who designed a machine for the oyster farming industry as a part of their end-of-year project during their second year.

“We were paired with a client to build a solution for a real industry problem,” said co-founder Jordan Sampson in an interview from Charlottetown.

Sampson, along with classmates-turned-business-partners Dylan MacIssac and Brett McDermott, built a device that flips oyster cages, which is a critical and labour-intensive task for fishermen in the industry.

In oyster farming, the shellfish are grown in floating cages that need to be flipped often during growth to kill off parasites like barnacles, algae and mussels. When the cages are flipped, these parasites are exposed to the sun, which kills them.

“Currently the cages are all flipped manually, usually by two or three guys and (the cages) weigh about 200 or 300 pounds,” said MacIsaac. “They also work right up until the ice forms. They’re basically doing 200-pound dead lifts for 10 to 12 hours a day.”

With help from UPEI and Synapse, an accelerator at UPEI, the students were shown just how big the potential market is for their oyster-flipping technology.

The province’s oyster sector reportedly had its biggest catch this year. According to Statistics Canada, the industry produced 3,422 tonnes of farmed oysters in 2015 alone. P.E.I. is known for its Malpeque oysters and produces roughly 30 per cent of the farmed oysters in Canada.

To date, the young company has raised $55,000 in non-equity funding with $20,000 from Springboard Atlantic and $25,000 from Innovation P.E.I.’s Ignition Fund. The co-founders plan to use the funds to help produce their prototype.

Ocean Executive Adds 2 International Clients

The team is also enrolled in the Creative Destruction Lab in Halifax and completed the first session in November.

Sampson said the CDL program has opened their eyes to the business side of the machine and said the company has a lot of catching up to do in terms of business knowledge.

“It made it very clear to us that we were the underdogs in the room.” said Sampson who will return to Halifax in January for the next CDL session. “They’ve been helping us with the business side and helping us get to market.”

The co-founders, who all grew up on the Island, built everything on-site at UPEI. They took advantage of the resources from the university’s engineering department and worked on the prototype between their classes.

In 2018, the company will finalize its boat attachment design and iron out last-minute kinks — the team tested its last prototype before winter and with good success.

“The concept is definitely proven — there are just a few small changes that need to be made,” said Sampson.

As the ice settles on the oysters in the Malpeque Bay, Island AquaTech is working to make the growing process much simpler (and certainly less cold) for P.E.I.’s fishermen.

Said Sampson: “We had one guy say to us: ‘I don’t care how it works, as long as it gets me out of the water.’”