Metamaterial Technologies Inc. has closed a $3.1 million round of funding, which will help the Dartmouth company with its ambitious plans to establish a metamaterials R&D and pilot production facility in Nova Scotia.

The company – which has developed revolutionary materials that deflect, enhance or absorb light -- has raised $2 million from Innovacorp. It comprises a $1.5 million venture capital investment and a $500,000 non-dilutive contribution from the innovation agency’s cleantech fund.

The company has also raised $1.1 million from private investors, including an undisclosed contribution from the First Angel Network, the Halifax-based angel group. FAN arranged for Founder and CEO George Palikaras to also pitch to the Wilmington Investor Network, and the size of the round may rise once the Wilmington angels come in.

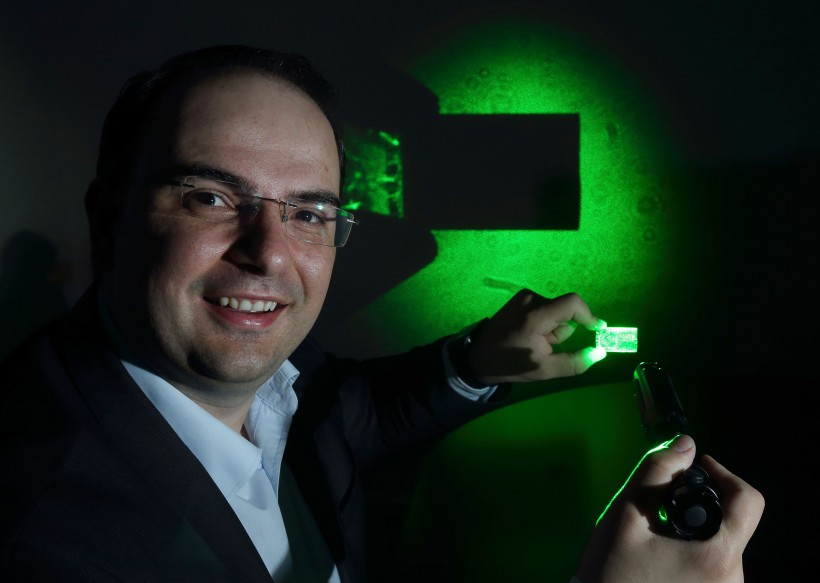

Palikaras has developed optical metamaterials — nano-composites with properties not found in nature — that are capable of filtering, absorbing or enhancing light. The technology is the basis of Metamaterial Technologies, which comprises three main divisions: Lamda Guard, which filters specific forms of light to protect vision; Lamda Solar, which focuses on doubling solar energy efficiency; and Lamda Lux, which can increase the output of LED lighting by up to 10 times.

“They’re miles ahead of anything else in that space,” said Ross Finlay, the Co-Founder of the First Angel Network. “It’s like being the lead dog in a dog sled race. If you’re not the lead dog, the view doesn’t change much.”

Lamda Guard, the unit that filters light, is now developing the company’s first product, metaAIR, a transparent thin-film that can filter out laser beams and deflect light. Last year, the company struck a partnership with Airbus, the world’s largest airplane manufacturer, to develop and test metaAIR to help prevent laser attacks on aircraft cockpits.

With the new funding, Metamaterial will begin to develop an R&D and pilot production facility that will allow the manufacture of these thin-films for cockpit windows. Facilities now exist that would allow the production of the screens on a small basis, for goggles and visors. But Palikaras wants to produce larger screens.

“This is a true game-changer,” said Palikaras. “Until now, these nano-structured materials have been too expensive to produce in large sizes. But through our research and in partnership with vendors and suppliers, we are investing and developing new manufacturing processes that allow for cost effective large scale and volume production capabilities. So far, the state-of-the-art has been a few centimeter-squared size and we are going to metre-squared.”

Metamaterial Technologies, which now has seven employees, will need more capital and staff to meet Palikaras’ plans and industry demand. It’s difficult to say how much capital it will need because it will depend on how quickly it can bring in money from its aerospace product. The CEO pointed out that aerospace is a regulated market, and producing innovation in a regulated industry takes time due to all the approvals.

But the company is moving forward, and has recently opened an office in Los Angeles and hired its eighth employee.

“We want to grow this company to achieve the full potential, which means we will need more capital,” said Palikaras.

Entrevestor receives financial support from government agencies that support start-up companies in Atlantic Canada. The sponsoring agencies play no role in determining which companies are featured in this column nor do they have the right to review columns before they are published.